A Yogurt Cup Injection Mould is a precision-engineered tool specifically designed to manufacture the plastic containers used for packaging yogurt and other dairy or food products. This mould is installed in an injection moulding machine where thermoplastic resin, typically polypropylene (PP) or polystyrene (PS), is melted and injected under high pressure into the mould cavity. The cavity defines the exact shape, size, wall thickness, and often the decorative texture or branding of the final cup. Once the plastic cools and solidifies, the mould opens to eject a finished yogurt cup, ready for filling and sealing. The design and quality of the Yogurt Cup Injection Mould are critical for achieving consistent cup quality, high production speeds, and compliance with strict food safety standards.

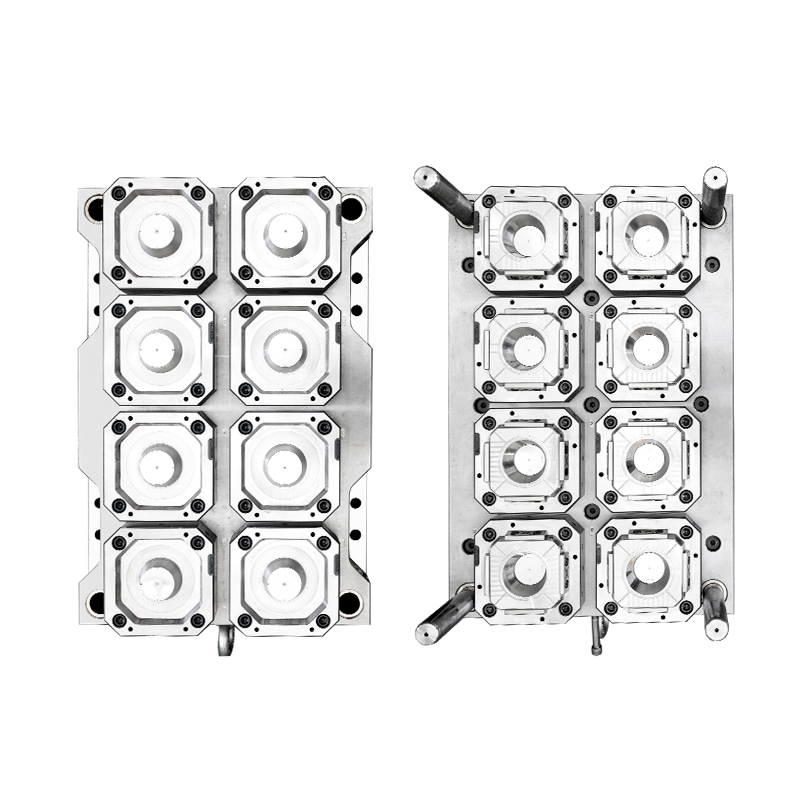

The construction of such a mould demands expertise in toolmaking and food-grade manufacturing requirements. It is typically built from high-grade, corrosion-resistant stainless steel or hardened tool steel, polished to a mirror finish to prevent bacterial adhesion and ensure easy release. The mould consists of a core and cavity; the core forms the cup's interior, while the cavity shapes its exterior and rim. A critical feature is the cooling system—a network of channels within the mould blocks through which temperature-controlled water circulates. Efficient cooling is paramount to achieve a fast production cycle and prevent warping. An ejection system, often using pins or a stripper plate, cleanly removes the cup from the core.

Regular maintenance, including thorough cleaning and inspection of sealing surfaces and moving components, is essential to prevent contamination and ensure longevity. The operational reliability of a well-designed Yogurt Cup Injection Mould is foundational to the efficiency of the entire food packaging line, enabling the high-volume, hygienic production of containers that protect product integrity from factory to consumer.