Across industries such as energy, heavy equipment, aerospace, and chemical processing, component reliability has become non-negotiable. Stainless steel rings, often operating under high loads, pressure, or corrosive environments, must meet increasingly strict dimensional and metallurgical standards.

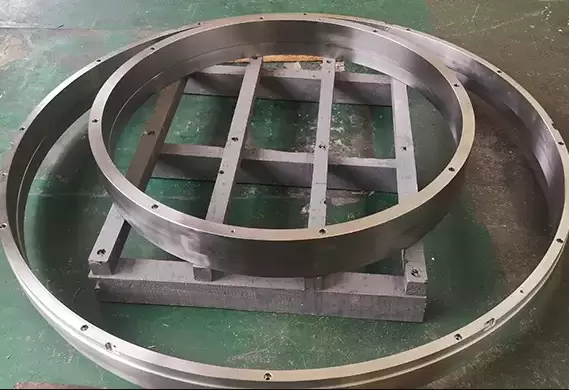

This has driven strong demand for stainless steel ring forging precision machining, a manufacturing approach that combines the structural advantages of forging with the dimensional accuracy of advanced machining. As an experienced manufacturer, Jiangxi Hongdu Preciosion Machinery specializes in delivering forged and machined ring components engineered for long-term performance in demanding service conditions.

Why Forging Is the Foundation of High-Performance Stainless Steel Rings

1. Grain Flow Optimization and Structural Strength

Forging reshapes metal through controlled plastic deformation, aligning the internal grain structure with the ring’s geometry. Compared to casting or machining from plate, forged stainless steel rings offer:

Higher fatigue resistance

Improved impact toughness

Reduced internal defects

These characteristics are essential for applications such as flanges, bearing rings, pressure vessels, and rotating equipment.

2. Material Integrity in Harsh Environments

Stainless steels used in ring forgings—such as 304, 316, 321, 410, and duplex grades—must retain mechanical properties under thermal stress and corrosion exposure. Proper forging practices ensure consistent material density and performance throughout the cross-section.

Precision Machining: Where Accuracy Meets Functionality

Forging establishes strength, but precision machining defines usability. Stainless steel ring forgings typically require tight tolerances on:

Inner and outer diameters

Flatness and parallelism

Groove geometry and sealing surfaces

Modern CNC machining centers allow manufacturers to achieve micron-level accuracy while maintaining surface integrity.

At Jiangxi Hongdu Preciosion Machinery, precision machining is tightly integrated with forging processes, ensuring dimensional consistency from raw forging to finished component.

Controlling Tolerances in Stainless Steel Ring Forging Precision Machining

1. Machining Challenges of Stainless Steel

Stainless steel presents unique machining challenges, including:

High work-hardening tendencies

Lower thermal conductivity

Tool wear due to material toughness

Precision machining strategies must account for cutting parameters, tool selection, and cooling methods to maintain accuracy without compromising surface quality.

2. Process Control and Repeatability

Consistent results depend on rigorous process control, including:

CNC programming optimization

In-process dimensional inspection

Statistical process control (SPC)

These measures ensure repeatability across both small batches and large production runs.

Applications Requiring Stainless Steel Ring Forging Precision Machining

1. Energy and Power Generation

Forged and machined stainless steel rings are widely used in turbines, pressure systems, and pipeline connections, where strength and corrosion resistance are critical.

2. Heavy Machinery and Industrial Equipment

Bearing rings, gear components, and structural connectors benefit from the fatigue resistance provided by forged stainless steel combined with precise machining.

3. Chemical and Marine Industries

In corrosive environments, precision-machined stainless steel rings ensure reliable sealing and long service life, reducing downtime and maintenance costs.

Quality Assurance and Material Traceability

High-performance ring components demand strict quality standards. Professional manufacturers implement comprehensive quality systems covering:

-

Raw material certification and traceability

-

Non-destructive testing (UT, PT)

-

Dimensional and surface inspection

Jiangxi Hongdu Preciosion Machinery maintains documented quality procedures to ensure every stainless steel ring meets customer and industry specifications.

Customization and Engineering Support

Every application imposes unique requirements. Stainless steel ring forging precision machining allows for:

-

Custom dimensions and cross-sections

-

Specialized surface finishes

-

Heat treatment tailored to mechanical needs

Engineering collaboration at the early design stage helps optimize material usage, machining efficiency, and overall cost-performance balance.

Conclusion

Stainless steel ring forging precision machining represents the convergence of metallurgical strength and dimensional accuracy. In applications where failure is not an option, this manufacturing approach delivers components capable of withstanding extreme mechanical and environmental demands.

With proven expertise in both forging and precision machining, Jiangxi Hongdu Preciosion Machinery supports global industries with reliable stainless steel ring solutions designed for performance, longevity, and compliance with stringent technical standards.