Diamond hole saws are specialized tools used for cutting hard materials such as ceramics, glass, stone, and concrete. A Diamond Hole Saw Manufacturer plays a crucial role in producing these tools, combining high-quality materials, precise engineering, and rigorous quality control to ensure reliable performance across various applications. By supplying durable and accurate cutting solutions, these manufacturers meet the demands of both industrial and professional users.

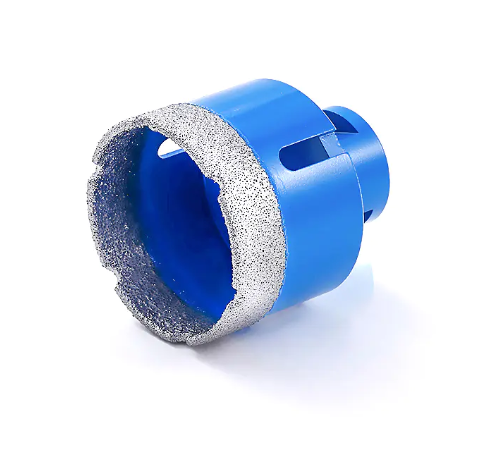

A Diamond Hole Saw Manufacturer typically uses industrial-grade diamonds bonded to a steel core or another durable base material. The diamond particles provide exceptional hardness, allowing the saw to cut through dense or abrasive surfaces efficiently. Careful selection of diamond grit size and bonding techniques ensures both cutting efficiency and tool longevity.

Precision is a primary focus for a Diamond Hole Saw Manufacturer. Each saw undergoes strict dimensional inspections and performance testing to ensure that the diameter, cutting depth, and core alignment meet industry standards. This attention to detail allows users to achieve clean, accurate holes without chipping or damaging the surrounding material.

Durability is another key aspect of products from a Diamond Hole Saw Manufacturer. High-quality bonding agents and a robust core design help maintain the structural integrity of the saw even under heavy use. This durability reduces the frequency of tool replacement, contributing to cost-effective operations in industrial or construction environments.

A Diamond Hole Saw Manufacturer often provides a range of sizes and designs to accommodate different materials and applications. Users can select saws with varying diameters, segment heights, and tooth arrangements to match specific cutting requirements. This versatility ensures that a single manufacturer can supply tools suitable for multiple tasks, from countertop installations to masonry work.

Efficiency is further enhanced by thoughtful design. Many saws from a Diamond Hole Saw Manufacturer feature segment patterns that improve cooling, reduce friction, and prevent overheating during cutting. This design helps maintain cutting speed and prolongs the life of the saw, allowing operators to complete projects with consistent results.

A Diamond Hole Saw Manufacturer also emphasizes safety and usability. Features such as pilot drills, stabilizing cores, and easy-to-mount arbors reduce the risk of slippage and improve control during operation. Proper instructions and recommended usage guidelines from the manufacturer help operators achieve precise results safely.

Support and customization are additional benefits of partnering with a Diamond Hole Saw Manufacturer. Many manufacturers can produce specialized saws for unique materials or project specifications, providing tailored solutions for industrial or commercial applications. This flexibility allows clients to meet specific operational needs efficiently.

A Diamond Hole Saw Manufacturer delivers durable, precise, and versatile cutting tools for a wide range of applications. Through careful material selection, rigorous quality control, and thoughtful design, these manufacturers ensure reliable performance and longevity. Working with a reputable diamond hole saw manufacturer allows operators to achieve accurate, efficient, and safe cutting results for materials that are otherwise challenging to process.