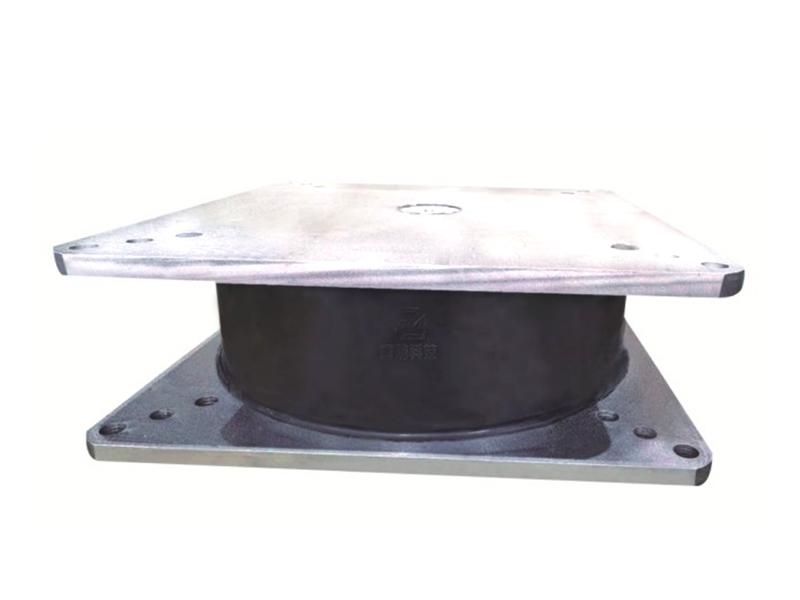

A linear rubber bearing is a specialized elastomeric component engineered to accommodate controlled linear movement while providing vibration isolation and load support. Unlike rotational bearings, this device operates along a single axis, utilizing the viscoelastic properties of rubber to absorb kinetic energy and reduce transmission of shocks. The bearing typically consists of layered rubber sheets vulcanized to metal plates, creating a composite structure that allows precise horizontal or vertical displacement. Its design enables structural systems to move freely within defined limits while maintaining stability under dynamic loads. This unique combination of flexibility and restraint makes the linear rubber bearing particularly valuable in applications where thermal expansion, seismic activity, or machinery vibrations must be managed without compromising structural integrity.

The operational effectiveness of a linear rubber bearing derives from its tailored material properties and geometric configuration. Engineers select rubber compounds based on hardness, damping characteristics, and environmental resistance—factors that directly influence the bearing's stiffness and durability. The metal plates, usually steel, provide anchorage points and prevent buckling under compression. When subjected to linear forces, the rubber layers deform elastically, storing and dissipating energy through internal friction. This action simultaneously cushions impacts and recenters the structure when forces subside. Advanced designs may incorporate guide mechanisms or lubricated interfaces to minimize friction during movement, ensuring smooth operation over extended service periods.

Installation of linear rubber bearing systems requires careful consideration of load paths, movement ranges, and environmental conditions. In bridge engineering, these bearings accommodate deck expansion caused by temperature fluctuations while supporting vehicular loads. For industrial machinery, they isolate sensitive equipment from ground vibrations or allow precise alignment adjustments. The bearings must be calibrated to specific stiffness values to avoid resonance with operating frequencies, a process often involving finite element analysis and prototype testing. Protective measures against ozone degradation, UV exposure, and chemical corrosion are integrated into the design to ensure long-term reliability in outdoor or harsh environments.

Maintenance protocols for linear rubber bearing installations include regular inspections for surface cracking, hardening, or permanent deformation. Non-destructive testing methods like ultrasonic scanning can detect internal delamination before visible signs appear. The continued innovation in polymer science and bearing design expands the capabilities of these components, allowing engineers to address increasingly complex challenges in infrastructure and mechanical systems. By enabling controlled linear motion with inherent damping characteristics, the linear rubber bearing provides an elegant solution for reconciling structural mobility with stability across countless engineering applications.