An AC Motor is an electromechanical machine that converts alternating current electrical energy into rotational mechanical energy. Its operation is primarily based on the principle of a rotating magnetic field. When multiphase AC power, most commonly three-phase, is supplied to windings (the stator) arranged around the motor's interior, it generates a magnetic field that rotates at a synchronous speed determined by the power supply frequency and the number of magnetic poles. This rotating field induces currents in the rotor, creating a second magnetic field. The interaction between these two fields produces torque, causing the rotor to turn and drive a load. The widespread adoption of AC power distribution has made the AC Motor the workhorse for countless applications requiring reliable and efficient motive power.

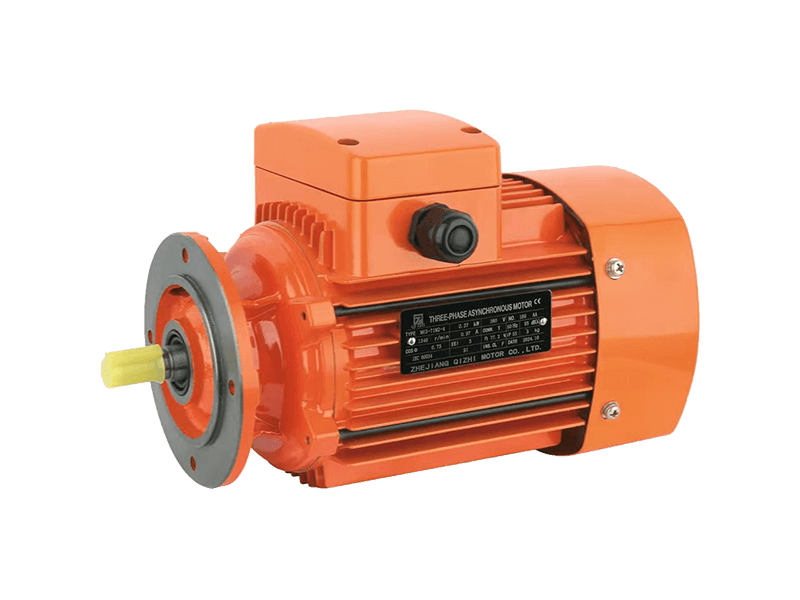

Two primary categories dominate the landscape: induction (asynchronous) motors and synchronous motors. The induction motor, particularly the squirrel-cage type, is the most common due to its simple, rugged construction and lack of electrical connections to the rotor. In this design, rotor current is induced by the stator's rotating field, hence the name. The synchronous motor rotates at a speed precisely locked to the supply frequency and is used where constant speed is critical. These fundamental designs are further adapted into countless subtypes and configurations to meet specific torque, speed, and environmental requirements. Enclosures range from open-frame designs to fully sealed units for harsh or hazardous locations.

Proper selection and operation of an AC Motor require understanding load characteristics, starting torque, duty cycle, and available power supply. With its combination of durability, efficiency, and relatively low maintenance needs, the versatile AC Motor remains an indispensable component powering fans, pumps, compressors, conveyors, and machine tools across global industry and infrastructure.