Linde HPR-02 series pumps (e.g., HPR-105, HPR-130, HPR-160) are high-performance variable-displacement units, widely respected in the heavy equipment industry for their exceptional power density, rapid response, and high efficiency. They are the heart of sophisticated hydraulic systems, particularly those using Linde’s Load-Sensing Control (LSC). However, the very precision that gives them their performance also makes them highly susceptible to internal wear. An internal leak in an HPR-02 pump is an insidious problem; it quietly bleeds away performance, leading to slow machine operation, chronic overheating, and ultimately, catastrophic failure. This expert guide provides a detailed analysis of how to diagnose and repair internal leaks in Linde HPR-02 pumps, with a critical focus on the adjustment and repair process.

Understanding the Enemy: What is an Internal Leak?

In a healthy HPR-02 pump, all the hydraulic fluid drawn from the tank is forced out the high-pressure port to do work (e.g., move a cylinder or hydraulic motor). An internal leak, or "bypass," occurs when high-pressure fluid finds an easier path inside the pump and leaks back to the low-pressure side (the case or the inlet) instead of going to the machine’s actuators. This creates two immediate problems:

- Loss of Volumetric Efficiency: The pump is no longer delivering its full rated flow (LPM/GPM), causing the machine's functions to become slow and weak.

- Rapid Heat Generation: The high-pressure fluid escaping through these internal gaps creates intense friction. This energy is not converted into work but is released directly as heat, causing the entire hydraulic system to overheat, which further degrades the fluid and accelerates wear.

Primary Causes of Internal Leaks in an HPR-02 Pump

Internal leaks are not random; they are a direct result of wear or damage to the pump's high-precision rotating group and control components.

- Abrasive Contamination: This is the #1 killer of all hydraulic pumps. Microscopic particles of dirt or metal in the hydraulic fluid act as a grinding paste. They get caught between the rotating cylinder barrel and the stationary valve plate, cutting grooves and wear-paths into these mirror-finished surfaces.

- Worn Piston Shoes: The "shoes" that ride on the swashplate wear down, allowing high-pressure fluid to leak past the piston, reducing the pump's efficiency.

- Fluid Degradation: Operating the system at excessive temperatures (often caused by the leak itself) or using the wrong type of hydraulic fluid breaks down the oil's viscosity. This "thin" oil cannot maintain the critical lubricating film, leading to metal-on-metal contact and accelerated wear.

- Worn Compensator/Regulator Spools: The HPR-02's regulator is a highly complex valve that controls the swashplate angle. If the spools inside this regulator become worn (again, usually from contamination), they will leak internally. This causes the pump to respond slowly or fail to "de-stroke" or "up-stroke" correctly, leading to massive inefficiency and heat.

Diagnostic Methods: Pinpointing the Leak

Before starting any repair, you must confirm the pump is the source of the problem, and not a faulty relief valve or cylinder elsewhere in the system.

- Symptom Analysis: The classic signs of severe internal leakage in a pump are:

- Slow hydraulic operation across all machine functions.

- Significant loss of power under load (e.g., the machine stalls easily).

- The system overheats very quickly, often within 30-60 minutes of starting work.

- A healthy HPR-02 at full load may have a case drain flow of 3-5 liters per minute (check the specific manual).

- A worn-out pump with severe internal leaks can have a flow of 30, 50, or even 100 liters per minute. This gushing flow is a direct measurement of the pump's inefficiency and confirms it is internally destroyed.

Repair and Adjustment: A Precision Process

Once diagnosed, repairing an HPR-02 pump is a highly specialized task. A "seal kit" will not fix an internal leak. The repair must address the metal-to-metal wear.

- Disassembly and Lapping: The pump must be disassembled in an immaculately clean environment. The most critical step is the lapping (precision grinding/polishing) of the cylinder barrel and valve plate. These two surfaces must be perfectly flat to a mirror finish to create a proper seal. If they are scored, they must be lapped or replaced.

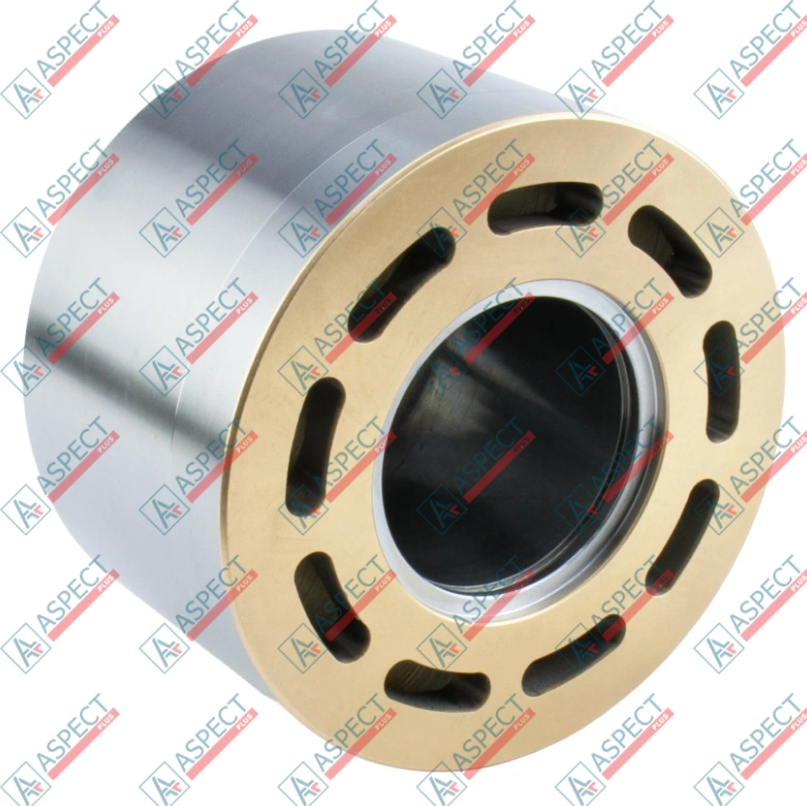

- Rotating Group Replacement: In cases of severe wear, the entire rotating group (cylinder barrel, pistons, and swashplate/cradle assembly) is replaced as a matched, balanced set.

- Regulator Rebuild: The regulator itself must be disassembled, cleaned, and inspected. Worn spools or fatigued springs must be replaced with genuine Linde parts to restore the correct load-sensing response.

- The Critical Adjustment Phase: A rebuilt pump is not a functional pump until it is calibrated. This adjustment must be done on a hydraulic test bench.

- Standby Pressure: Adjusting the pump's standby (neutral) pressure.

- Pressure Cut-Off (Main Relief): Setting the maximum pressure at which the pump "de-strokes" to zero flow.

- Load-Sensing (LS) Signal Adjustment: Calibrating the "margin pressure"—the small pressure differential that tells the pump how to react to operator demand.

Attempting to adjust these settings on the machine "by ear" or "by feel" is a guaranteed way to create an inefficient or dangerous system. The test bench is the only way to verify the pump is functioning correctly across its entire operational map.

Our company, Aspect Plus, specializes in providing the genuine-spec, high-quality spare parts essential for a professional Linde HPR-02 repair, including rotating groups, seal kits, and regulator components.

Conclusion

Internal leaks in a Linde HPR-02 pump are a serious failure that directly leads to a loss of machine performance and severe overheating. The primary cause is almost always hydraulic fluid contamination, which erodes the pump's precision internal components. Accurate diagnosis via a case drain flow test is essential to confirm the failure. A successful, long-lasting repair is not a simple parts swap; it is a complex remanufacturing process involving lapping, replacement of the rotating group with quality parts, and precise calibration of the regulator on a test bench.

For expert consultation on hydraulic diagnostics and a reliable source for high-quality Linde spare parts, contact the specialists at Aspect Plus.