Jar Preform Mould manufacturing plays a crucial role in the production of PET jars used across food, beverage, and cosmetic industries. The quality of a preform mould directly influences the transparency, strength, and uniformity of the final containers. As packaging standards continue to rise, manufacturers are focusing on precision, durability, and consistent performance in mould development.

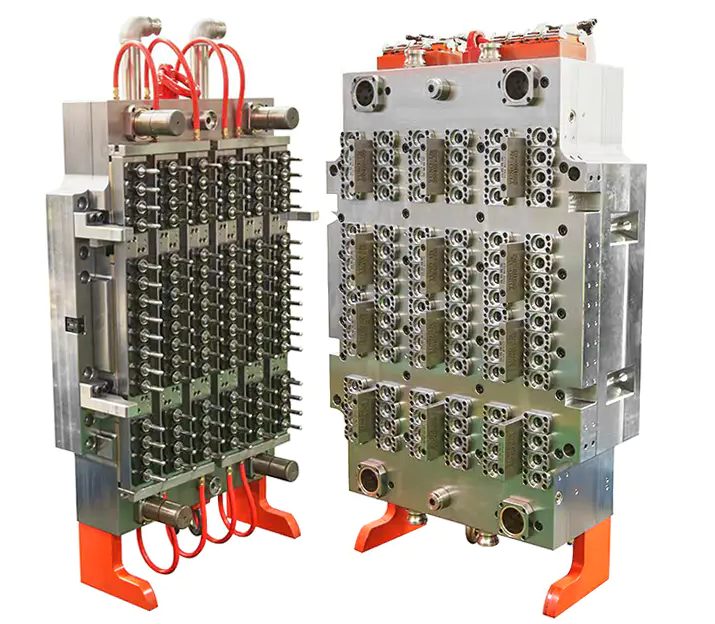

A Jar Preform Mould is typically designed with multi-cavity structures to achieve high productivity. The number of cavities may vary depending on the jar size, wall thickness, and material type. Each cavity must maintain consistent dimensions to ensure that all preforms meet strict quality requirements during injection moulding.

Taizhou Huangyan Yuanneng Mould Co., Ltd. has extensive experience in mould design and production. The company applies advanced software for 3D modeling and flow analysis to optimize gate design, cooling systems, and cycle efficiency. By simulating material flow, engineers can reduce deformation, shorten cooling time, and enhance mould balance.

Material selection is another key factor. Hardened stainless steel or high-grade tool steel is commonly used to ensure corrosion resistance and long service life. Precision machining and polishing techniques are applied to create smooth mould surfaces, resulting in clear and defect-free PET preforms.

The cooling system is an essential component in Jar Preform Moulds. Efficient temperature control not only stabilizes product dimensions but also reduces production cycle time. Proper cooling helps minimize shrinkage, ensuring that the preforms maintain uniform thickness and clarity after blowing.

Maintenance and cleaning are also critical for long-term mould performance. A well-structured mould design allows easy disassembly, inspection, and replacement of components. Regular maintenance extends service life and maintains stable product quality.

In modern production, automation is increasingly integrated into the Jar Preform Mould process. Automated systems improve productivity, reduce manual errors, and provide better consistency. From small cosmetic jars to large food containers, precise mould engineering ensures that every product meets functional and aesthetic requirements.

The continuous improvement of mould technology supports industries that depend on durable, safe, and attractive PET jars. Through advanced design and strict quality management, Jar Preform Moulds help manufacturers produce containers that meet diverse market demands while maintaining efficiency and precision.