Power tools are widely used in construction, manufacturing, and DIY projects, and their performance largely depends on the quality of internal components. The Stator For Power Tools is one of the most important elements in electric motors, responsible for generating a magnetic field that drives the rotor.

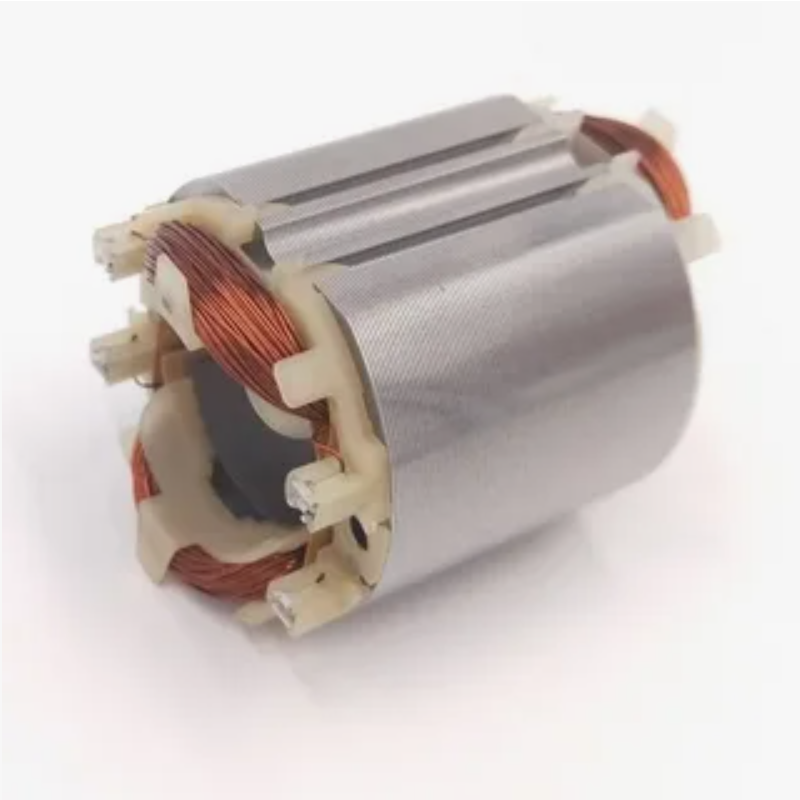

A Stator For Power Tools typically consists of laminated steel cores and copper windings. The steel core provides structural integrity and magnetic conductivity, while the copper windings carry electrical current to create the magnetic field necessary for motor operation. High-quality materials in the stator ensure that the power tool operates efficiently, maintains torque, and prevents overheating during prolonged use.

Design and engineering play a crucial role in producing a Stator For Power Tools. The number of poles, winding configuration, and core geometry are carefully calculated to match the motor specifications. These parameters affect the tool's speed, power output, and energy efficiency. A precisely engineered stator contributes to smoother operation, reduced vibration, and longer service life for the power tool.

Manufacturing quality is another essential factor for a Stator For Power Tools. The core laminations must be aligned accurately, and windings must be insulated properly to prevent short circuits or electrical losses. Factories often use automated winding machines and quality inspections to ensure consistency across production batches. Reliable manufacturing processes help reduce tool failure and maintenance costs.

A Stator For Power Tools also needs to withstand heat, mechanical stress, and electrical fluctuations. High-quality insulation materials, secure winding placement, and robust core construction ensure that the stator maintains performance even under demanding conditions. This durability is important for power tools used in industrial settings, where motors often operate continuously for extended periods.

Customization is an important consideration in the production of a Stator For Power Tools. Different power tools, such as drills, grinders, saws, and sanders, require stators with specific sizes, winding patterns, and power ratings. Manufacturers can adapt the stator design to meet these requirements, ensuring compatibility with the motor and overall tool performance. Custom options also allow for integration into cordless, corded, or brushless motor systems.

Maintenance and inspection of a Stator For Power Tools are critical for prolonging the life of the tool. Regular checks for insulation wear, winding integrity, and core condition help prevent motor failure. Replacing a worn or damaged stator restores performance and ensures that the power tool operates safely and efficiently.

A Stator For Power Tools is a vital component that directly influences motor efficiency, torque, and durability. By focusing on material quality, precise engineering, proper manufacturing, and customization, manufacturers provide stators that meet the demands of various power tools. For both professional and home users, understanding the role and characteristics of a stator helps in selecting, maintaining, and optimizing the performance of their equipment.