Polypropylene (PP) woven bags are widely used in industries such as agriculture, food packaging, construction, and retail. A PP Woven Bag Factory plays a vital role in producing these durable and versatile bags, ensuring they meet performance, safety, and functional standards.

A PP Woven Bag Factory typically starts by selecting high-quality polypropylene materials. The raw material must provide strength, flexibility, and resistance to tearing or puncturing. Quality material ensures that the finished bags can carry heavy loads, protect contents from moisture and dust, and withstand the demands of storage and transport. Proper material selection is a key step in delivering consistent and reliable products.

The manufacturing process in a PP Woven Bag Factory involves several precise steps. First, the polypropylene resin is extruded into thin threads. These threads are then woven into fabric sheets using looms. After weaving, the sheets undergo processes such as cutting, printing, and stitching to create finished bags. Each stage requires attention to detail to maintain uniformity, durability, and accuracy in size and weight.

Quality control is an important focus for a PP Woven Bag Factory. Finished bags are tested for strength, stitching quality, and resistance to wear and tear. Factories may conduct burst tests, drop tests, and tensile strength assessments to ensure the bags meet the required specifications. Consistent quality control guarantees that clients receive bags capable of handling industrial applications without failure or damage.

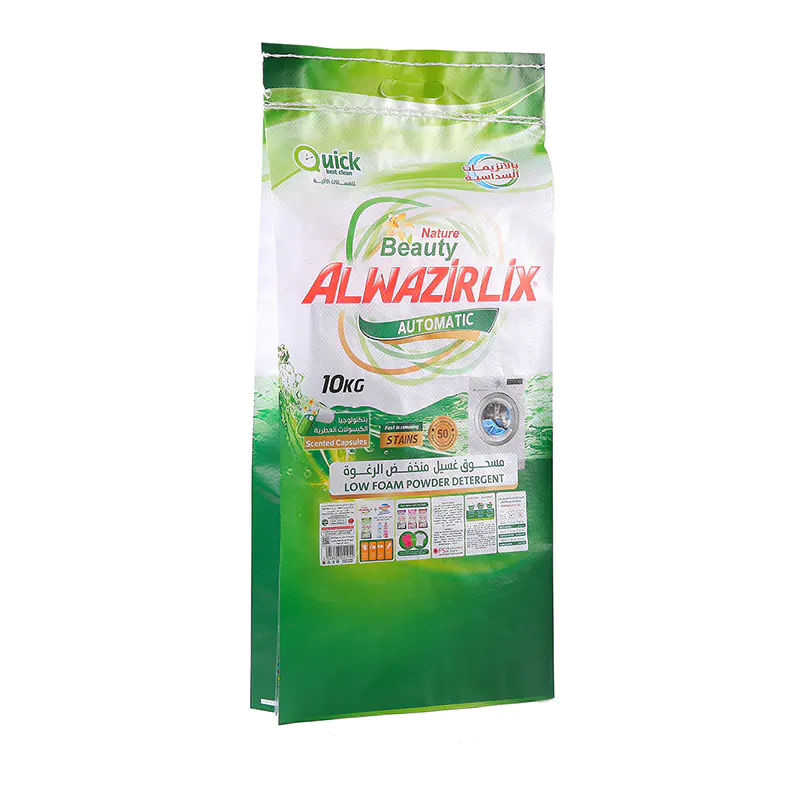

Customization is another important feature provided by a PP Woven Bag Factory. Clients often require specific bag sizes, colors, printing designs, or additional features such as laminated coatings for waterproofing. By offering customization options, factories can cater to diverse business requirements, including branding and compliance with specific industry standards. Customized PP woven bags enhance both functionality and presentation for end-users.

Durability and cost efficiency are key considerations in a PP Woven Bag Factory. By using high-quality polypropylene and precise manufacturing techniques, factories can produce bags that maintain strength under heavy loads while keeping production costs manageable. This balance between quality and cost makes these bags a practical choice for businesses seeking reliable and affordable packaging solutions.

A PP Woven Bag Factory also emphasizes sustainability. Many factories now produce recyclable and reusable PP woven bags to reduce environmental impact. By focusing on eco-friendly practices, factories support businesses looking to adopt greener packaging strategies, while maintaining the strength and durability that customers expect.

Logistics and timely delivery are also part of the operations of a PP Woven Bag Factory. Finished bags are packaged securely to prevent damage during transport, and efficient supply chains ensure clients receive their orders on schedule. Reliable delivery and consistent quality help businesses maintain smooth production and distribution processes.

A PP Woven Bag Factory combines high-quality materials, precise manufacturing, quality control, customization, and sustainable practices to produce durable and versatile packaging solutions. By understanding the operations and capabilities of such a factory, businesses can select suppliers who meet their functional and branding needs. PP woven bags from a reliable factory offer strength, durability, and adaptability, making them a practical choice for a wide range of industries.